Rick Mullins wrote: I can't quite figure out how you have the two wings fastened in the center, it looks like you didn't use the aluminum plates the plans described.

Hi Rick,

I've made a three part wing, with the centre 16' span all in one piece. I don't (didn't) have any metal brackets at the root of the wing as in the original drawings, but instead laminated in a pair of thick carbon load transfer bars between the two #1 ribs. These have the strength (on paper!) to carry the compressive and tensile loads... but I clearly didn't take compressive buckling into account.

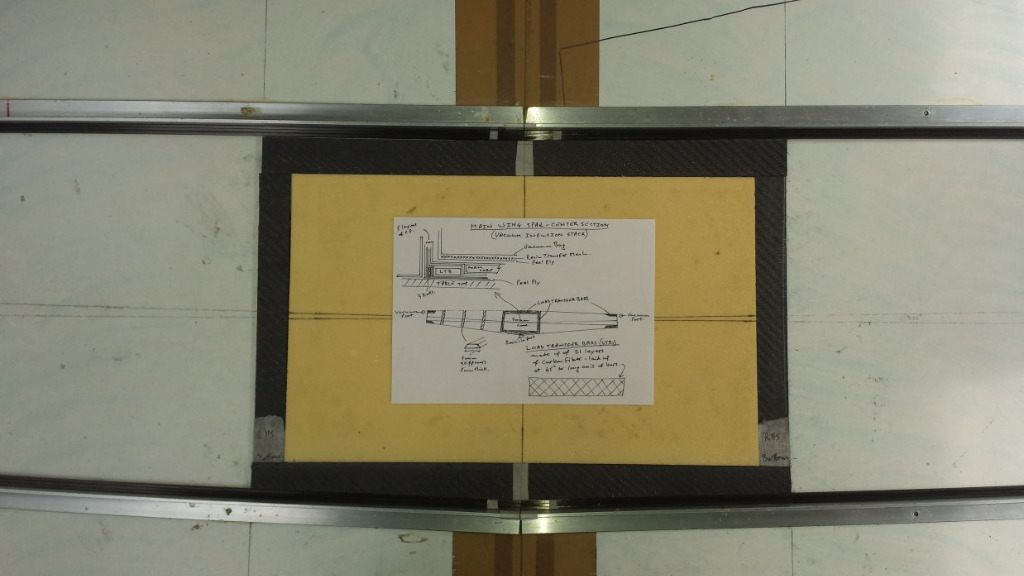

Here's a drawing of how the centre, root section was laid up:

The spar cap flange between the two #1 ribs is only 10mm deep and is unsupported by the leading edge skins. In hindsight, this was an obvious point of failure. My fix is to bolt a pair of 10mm aluminium plates to the upper spar cap (front and back), through the solid carbon LTB, and another one on the lower spar cap LTB just for good measure.

Watch this space...!